|

|

|

|

|

|

Steelcraft rolling metal fire doors are constructed in strict accordance with Underwriter's laboratories specifications and are approved by the New York City Board of Standards and Appeals.

|

|

|

|

|

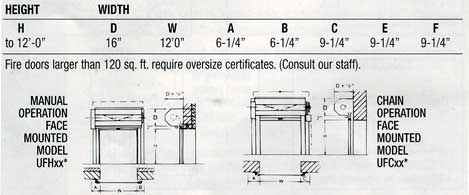

Standard Specifications for Rolling Fire Doors.

FURNISH: Every Rolling steel fire door is manufactured by Steelcraft Folding Gate Corp., bears Underwriter's Laboratories Classification as well as New York City Board of Standards and Appeals Labels.

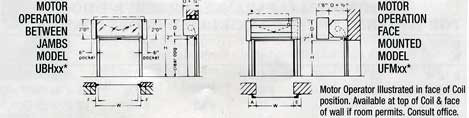

OPERATION:

Choose from Manual, Hand Chain Hoist or Electric Motor Operator.

CURTAIN: Is constructed of interlocking galvanized steel slats design #2 in 20 U.S. gauge (specially treated for

paint adhesion). They're fitted with steel or malleable iron endlocks riveted to each slat. This prevents curtain shifting and excessive wear on surfaces between the guides.

BOTTOM BAR:

Tough curtain rigidity is added to the bottom bar with two steel angles (with neoprene rubber astragal) (reversing safety edge for motor operated doors.)

COUNTER BALANCE ASSEMBLY:

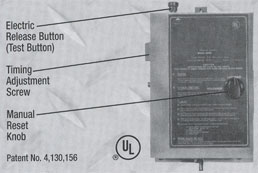

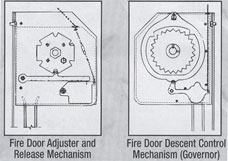

Is a custom engineered permanently lubricated torsion spring assembly enclosed in a structural steel pipe of sufficient diameter and wall thickness so deflection will not exceed .03" per foot of door width. The self closing mechanism is activated by fusible links or solenoid release.

BRACKETS: Minimum 5/16" thick - to contain the counterbalance assembly and rolled curtain.

GEAR ASSEMBLY FOR HAND CHAIN HOIST DOORS:

Ease of operation is assured with high quality gray iron cast gears from machine cut patterns.

GUIDES AND MOUNTING ANGLES:

Are designed to meet the door's specific engineering requirements and are a minimum 3/16" thick!

HOOD: Is formed of hot dipped galvanized sheet metal (treated for paint

adhesion) not lighter than 24 gauge and formed to fit end brackets.

LOCKING: Choose slide bolts on bottom bar, chain lock, or self locking on motor operated doors.

FINISH: All non-galvanized surfaces (except fraying surfaces) are coated with our rust inhibiting metal primer.

|

|

|

|

|

|

|

|

|

|